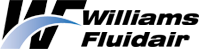

CUSTOM MANUFACTURED FITTINGS AND ADAPTERS

Since 1992, Williams Fluidair has manufactured custom fittings and adapters for Hydraulic, Pneumatic and other fluid conveying uses:

- Compression style tube fittings, flare tube fittings, braze tube fittings and conversion adapters

- Made to all ANSI, SAE, DIN and ISO thread specifications

- NPT / NPTF

- JIC 37º Flare

- SAE 45º Flare

- SAE O-ring (O-ring Boss)

- O-ring Face Seal

- British Standard Pipe (BSP)

- Metric

- Materials include Steel, Stainless Steel, Brass, Bronze and Aluminum

CUSTOM MANUFACTURED MANIFOLDS

Williams Fluidair manufactures custom manifolds for Hydraulic and Pneumatic applications

- Distribution manifolds for oil, air or water

- Hydraulic manifolds and sub-bases for directional control valves

- In-line cartridge valve manifolds for flow and pressure control

- Multi function manifolds with combinations of sub-plate mounted valves and cartridge valves

- Manifolds can be made in Aluminum or Cast Iron. Other materials on request.

- Cartridge valves can be Sun Hydraulics, Hydraforce or other common cavities.

- Threaded ports can be NPT, BSP, O-ring Boss, Metric, ISO6149

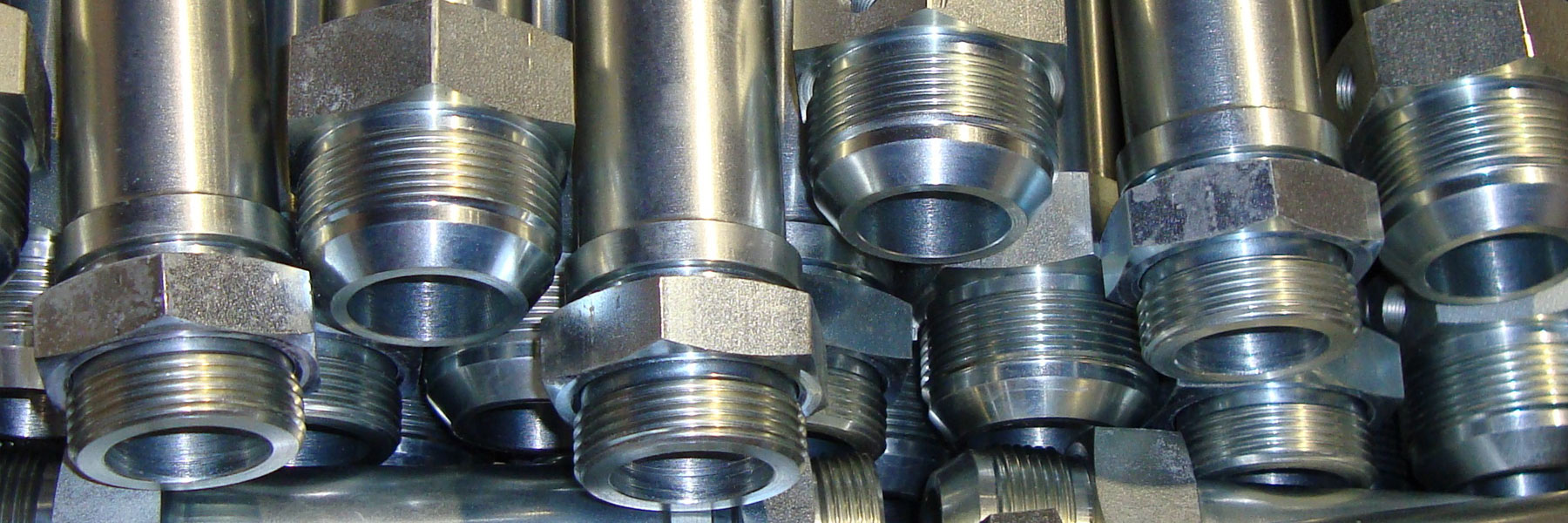

CUSTOM HYDRAULIC CYLINDERS

Williams Fluidair manufactures custom hydraulic cylinders for special applications

- Hydraulic cylinders with threaded and welded end caps for tree harvesting applications

- Hydraulic cylinders with threaded end caps for agricultural applications

- Hydraulic cylinders with integral hydraulic manifold for specific heavy vehicle applications

- Bore sizes up to 6 inches and cylinder strokes up to 4 feet

- Cylinder ports can be a wide variety of threaded or flanged sizes

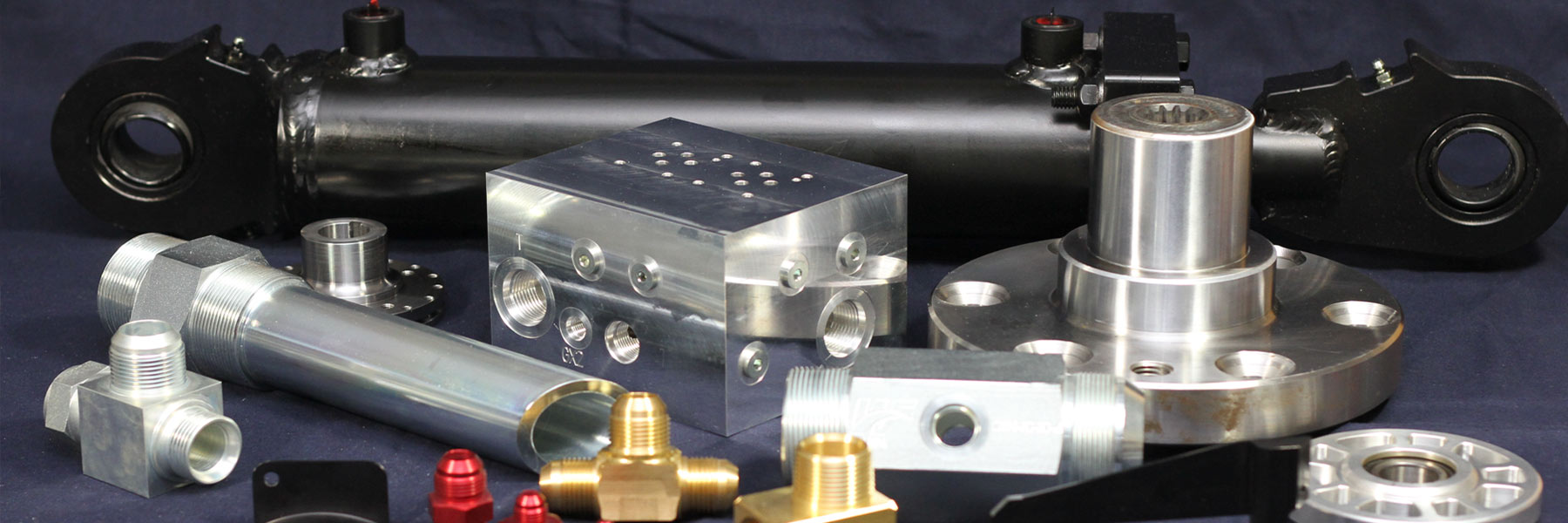

CUSTOM COMPONENTS

Williams Fluidair produces custom machined components for many different industries:

- Vehicle components for Military and Off-Road manufacturers

- Various components for waste management vehicle manufacturers

- Marine application manufacturers

- Office equipment manufacturers

- Laboratory test equipment manufacturers

- Vending machine manufacturers

We work closely with our customers from the time we receive their proposals until we ship the finished components to make sure all design, cost and quality objectives are met.